Cost – Effective And Simple Control Stepper Motors

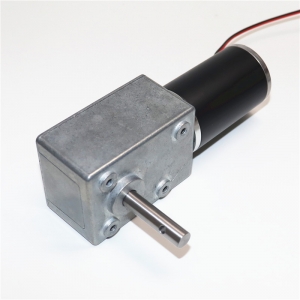

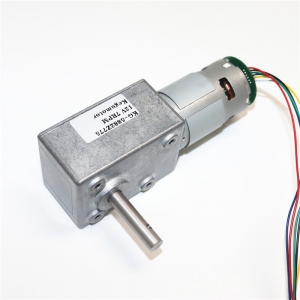

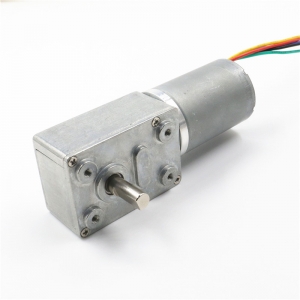

What is a Stepper Motor? 3.3V, 5V, 12V DC Stepper Motor With or Without Gearbox We can provide the 5V, 12V DC stepper motor with gearbox and encoders. Use the suitable ratio for your application. Factory direct stepping deceleration motor. A stepper motor is a type of electric motor that converts electrical pulses into mechanical rotation. Stepper motors are used in a wide variety of applications from automotive engines to 3D printers, learn more about the stepper motor working principle from kegumotor. Stepper motor is a brushless synchronous DC motor, adopting high quality motor steel material, responsive and can avoid system error.Low loss stators have better high speed performance. The small stepper motor divides a complete rotation into equal steps. Precise control of the motor’s position without any feedback mechanism. How do stepper motors work? Stepper motors are controlled by sending electrical pulses to the motor coils. The number of pulses sent determines the speed and direction of the motor. The most common type of stepper motor is the four-phase unipolar stepper motor. This type of motor has four coils that are energized in sequence to create rotation. What are the benefits of stepper motors? Stepper motors offer a number of advantages over other types of electric motors. They are highly precise and can be used in applications where precise positioning is required. Stepper motors are also relatively inexpensive and can be easily controlled with a microcontroller. What are some applications of stepper motors? Stepper motors are used in a wide variety of applications. Some common examples include 3D printers, computer hard drives, and automotive engines.