3.4mm Thickness Haptic Vibration Motor 12mm Diameter 1234

1.5$

Small Coin Vibrator Low Volume Pricing (USD)

| QTY BREAK | UNIT PRICE |

|---|---|

| 12+ | $3.00 |

| 100+ | $1.20 |

1000+ | $0.93 |

Ask for a quotation for mass production quantity, contact us or customizations and integration.

3.4mm Thickness Haptic Vibration Motor 1234 – 12mm Type With Lead Wire

ERM also called haptic vibration motors, compact and convenient to use, no external moving part. Used in handheld instruments haptic. 1234 Series haptic vibration motors – 12 mm x 3.4 mm, 3 V, small vibration motor for light weight wearable devices. Only 12 mm in diameter, 1234 series is currently the smallest haptic vibration motors on the market.

It was designed for devices requiring vibration alerts or haptic feedback. Because small vibration motor produces a relatively low vibrational force of 2.0 G, this motor is best suited for use in light weight devices placed directly against the user’s skin.

It may be driven by either DC voltage or a PWM signal. A driver IC is not required but may be used to produce various haptic effects. Custom foam pads, or PSA are available for mass production orders.

If a higher vibrational force is required, please consider using one of MDM’s larger sized haptic vibration, These motors range from 8 mm to 12 mm in diameter and can generate vibrational forces of up to 2.00 G.

Key Features

| Motor Model | 1234 wire length type |

|---|---|

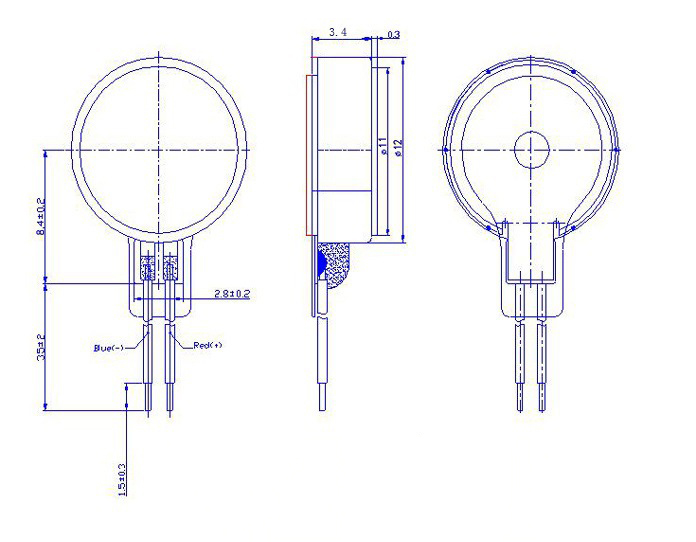

| Motor Diameter | 12.0mm ± 0.1mm |

| Motor Thickness | 3.4mm ± 0.1mm |

| Rated Voltage | 3.0V DC |

| Operating Voltage | 2.3V – 4.0V DC |

| Rated Speed | 11,000 ± 2,500rpm |

| Rated Current | 80mA max |

| Rotation Direction | CW (clockwise) or CCW (Contrary clockwise) |

| Operating Environment | -20~+60°C,Ordinary Humidity |

| Storage Environment | -30~+70°C,Ordinary Humidity |

| Nominal Amplitude Vibe Force | 1.65G |

12mm Pancake Vibration Motor Outline Drawing

Keywords:

haptic vibration, small vibration motor, pancake vibration motor

Development Samples:

Sampling quantities for stocked models are available for ordering directly from us online.

Engineering & Manufacturing:

Please contact one of our Sales Engineers for a quotation for production and consultation for customization and integration services.

Payment Method:

Payment methods : Paypal or T/T

Shipping Method:

1.Delivery: DHL door to door 5-7days.

2.Item will be shipped within 1-3 business days after the payment.

3.If you haven’t received the item on the Delivery Time, pls contact us by email if you have any questions. Normally, we will give you a reply within 24hours, if not, pls check the spam of your email box. We will do our best to help you solve the problems.

4.Please make sure your address is matched with the finally shipping address before you pay.

5.In order to ensure you receive your order tax free upon import, we will declare it with a lower value, pls be noted ,thanks!

FAQ & Frequently Asked Questions

Q: If customized, what information should you provide?

A: You need to provide the basic specification of the motor, such as: Dimensions, Sizes Applications, Voltage, Speed and Torque. It's better to offer application prototype drawings to us if possible.

Q: Do you provide technology support?

A: Yes. Our company have strong R&D capability and we can provide technology support if you need.

Q: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q: Sometimes I don't know the exact required parameter, how should I choose a suitable model ?

A: We can make some suggestions as long as you provide your specific requirement. We need to know what kind of product will bethis model used for ? And what does the working condition look like (duty cycles and load status)? And how long is the motor'sexpected lifetime ? etc. Then we can a make full assessment according to that.

Q:Is it possible for you to develop new motors if we provide the tooling cost?

A: Yes. Please kindly share the detailed requirements like performance, size, annual quantity, target price etc. Then we'll makeour evaluation to see if we can arrange or not.

Q: What's your main motors?

A: Diameter 4mm~42mm Dc Micro Motor And Gear Motor, Auto Dc Motor, Electric Motor, Gear Motor, Mini Dc Motor, Brush Dc Motor, Brushless Dc Motor, Spur Gear Motor, Micro Motor, Vibration Motor Etc.

Q: What's the main application of the micro dc motor?

A: Our mini DC motors are widely used in Home Applications, Office Equipment, Health-Care Application, Sanitation Industry, High-Class Toy, Banking System, Electronic and Electrical Tools, Automation Industry, Bank Equipments, Payment Equipments, Vending Machines, Power Door Lock, Electric Door Lock.

12mm Pancake Vibration Motor Mass Production

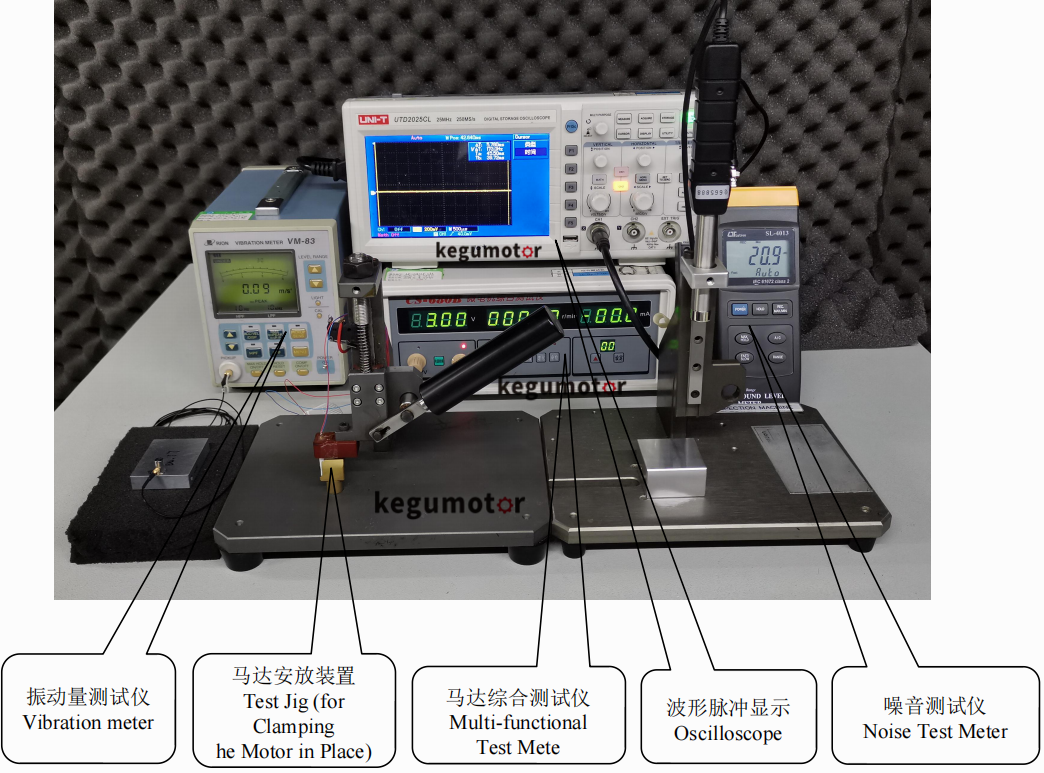

Micro Vibration Motor Test Before Shipment

Micro vibration motors have a high power density, which means they can produce a lot of power for their size.

They are also very efficient, so they don’t waste a lot of energy as heat.

Small vibration motors are also very rugged and can withstand a lot of abuse.

Very versatile and can be used for a variety of applications.

Finally, really affordable and are a great value for the money.

Custom design

Custom design

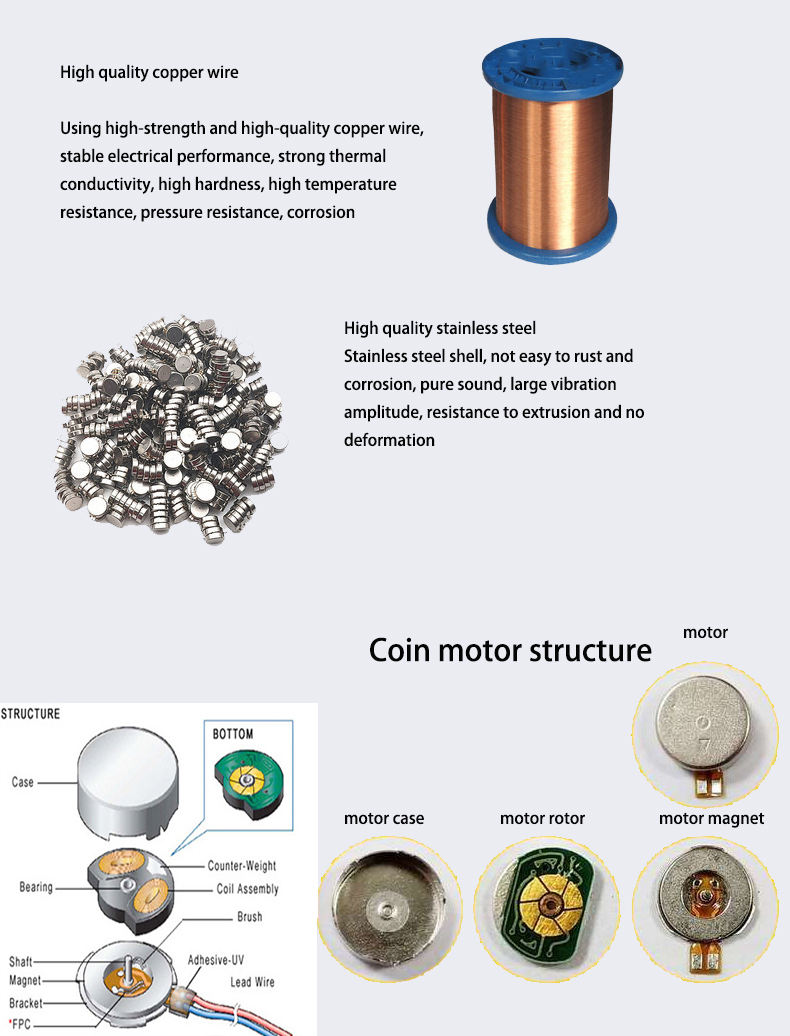

Enclosures can easily be moulded to accept the coin form of our shaftless vibration motors. Within the coin motor range, we offer both leaded and spring & pad mountable versions. Like all of our vibration motors, we are happy to quote for variations to the base design such as a modification to the lead length and also connectors.

How erm motor works:

There is an eccentric wheel on the motor shaft. When the motor rotates, the center mass point of the eccentric wheel is not on the rotation center of the motor, so that the motor is constantly out of balance, causing vibration due to inertia.

There are totally three kinds of coin vibration motors, LRA – linear resonant actuator(fast rising and brake time), BLDC – brushless DC coin motor(long lifetime), ERM – eccentric rotating mass. Generally we talk about coin vibration motors, also called as shaftless, pancake, disc vibrator motors, is to say the ERM type. For it’s widely used in advanced wearable devices, smart watches. It can be made as either FPC contract or wire leads types. Custom design with or without foam pads & adhesive on the top or bottom of the coin motors. It was designed for wearable devices that requires vibration feedback for alerting instead of physical buttons. Comparing with other ERMs(pager motors), coin vibration motor are more compact and convenient to use, particularly in handheld instruments where space should be carefully considered. Unlike cylindrical vibration motor, eccentric rotating mass of coin motor is located inside the case shell, which will significantly reduces the thickness and provide a stronger closure to the motor.

Typical applications are: Vibrating Bracelet, Finger Scanner, vibrating table motor, vibrating pager motor, vibrating motor radio shack, vibrating cell phone motor, furnace motor vibrating, toothbrush vibrating motor…