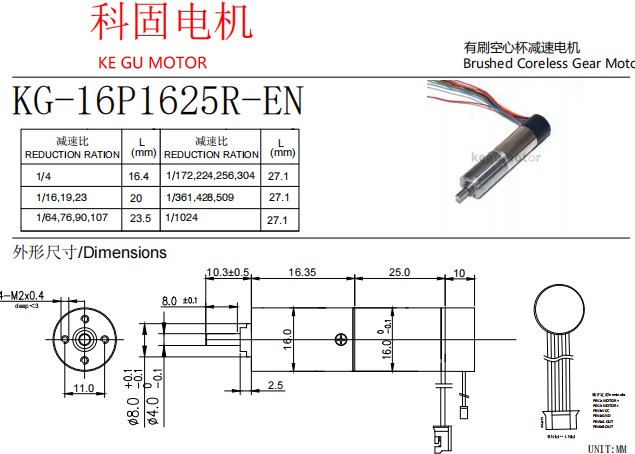

16mm Diameter 25mm Length Brushed Coreless Gear Motor With Encoder KG-16P1625R-EN

26.5$

Mini Coreless DC Gear Motor Small Volume Price (USD)

| QTY BREAK | UNIT PRICE |

|---|---|

| 1+ | $89.00 |

| 100+ | $67.00 |

| 1000+ | $26.50 |

Ask for a quotation for mass production quantity, contact us or customizations and integration.

KG-16P1625R-EN 16MM Brushed DC Gear Motors Mini Coreless Type Specifications

16mm Brushed Coreless Gear motor with encoder is a high-speed motor that is perfect for a wide range of applications. It features a high power density and low inertia, making it ideal for use in applications where space is limited. Additionally, the coreless design of this motor eliminates cogging and provides for smoother operation.

| Motor Model: | KG-16P1625R-EN brushed coreless gear motor |

|---|---|

| Body Diameter | 16.0mm ± 0.1mm |

| Body Length | 25mm ±0.3mm |

| Rated Operating Voltage | 6 V DC |

| No load Speed | 387 ± 10% rpm |

| No Load Current | 42 mA |

| Rated speed | 322 ± 10% rpm |

KG-16P1625R-EN 16mm 387RPM Micro DC Coreless Gear Motor Dimension

16MM Brushed Gear Coreless motor with encoder is coreless motor,encoder and gearbox, micro coreless motor is a type of electric motor that uses a permanent magnet to create torque, instead of using a winding around an iron core. This makes the motor lighter and more efficient. Coreless motors are used in applications where weight and efficiency are important, such as drones and RC vehicles

KG-16P1625R-EN 16mm Diameter Brushed Coreless Gear Motor 25mm Type With Encoder

16MM 1625R Brushed coreless gear motor with encoder also called hollow cup gear motor , compact and convenient to use, no external moving part. Used in handheld instruments haptic. 1625R Series Coreless Gear Motors ; 16 mm x 25 mm, 6 V, brushed coreless gear motor for precision devices. Only 16 mm in diameter, 1625R series is currently the high quality for medical equipment on the market.

It was designed for devices requiring high efficiency factors of up to 90 percent. Most of important, we can customize motor parameters for our customers which will give full play to product advantages.

It may be driven by either DC voltage or a PWM signal. A driver IC is required but may be used to produce various haptic effects.

If a higher force is required, please consider using one of ODM & larger sized coreless motor. These motors range from 4 mm to 40 mm in diameter and can generate higher forces .

Specification of the High Torque KG-16P1625R Series Brushed Coreless DC Gear Motor With Encoder

| Model | KG-16P1625R-EN-V1 | KG-16P1625R-EN-V2 |

|---|---|---|

| Voltage | 6V | 12V |

| No-load-speed | 387rpm | 637rpm |

| No-load-current | 42mA | 40mA |

| Load-torque | 125g.cm | 125g.cm |

| Load-speed | 322rpm | 592rpm |

| Load-current | 0.14A | 0.13A |

| Stall torque | 1139g.cm | 1856g.cm |

| Stall current | 1.0A | 1.35A |

Keywords:

coreless dc gear motor, small coreless gear motor, coreless electric motor,16mm motor,coreless motor with encoder

Sampling quantities for stocked models are available for ordering directly from us online.

Engineering & Manufacturing:

Please contact one of our Sales Engineers for a quotation for production and consultation for customization and integration services.

Payment Method:

Payment methods : Paypal or T/T

Shipping Method:

1.Delivery: DHL door to door 3-4days.

2.Item will be shipped within 1-3 business days after the payment.

3.If you haven’t received the item on the Delivery Time, pls contact us by email if you have any questions. Normally, we will give you a reply within 24hours, if not, pls check the spam of your email box. We will do our best to help you solve the problems.

4.Please make sure your address is matched with the finally shipping address before you pay.

5.In order to ensure you receive your order tax free upon import, we will declare it with a lower value, pls be noted ,thanks!

FAQ & Frequently Asked Questions

Q: If customized, what information should you provide?

A: You need to provide the basic specification of the motor, such as: Dimensions, Sizes Applications, Voltage, Speed and Torque. It's better to offer application prototype drawings to us if possible.

Q: Do you provide technology support?

A: Yes. Our company have strong R&D capability and we can provide technology support if you need.

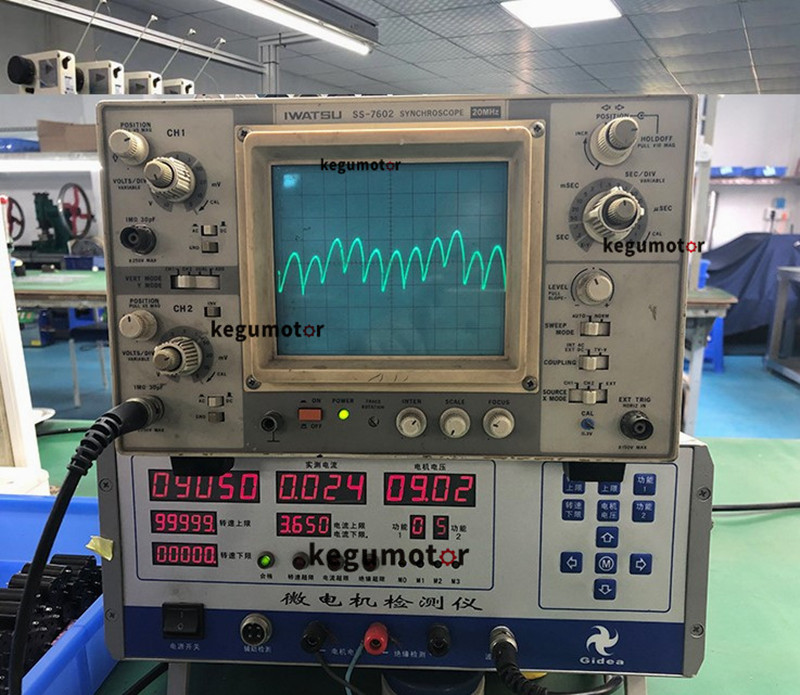

Q: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q: Sometimes I don't know the exact required parameter, how should I choose a suitable model ?

A: We can make some suggestions as long as you provide your specific requirement. We need to know what kind of product will bethis model used for ? And what does the working condition look like (duty cycles and load status)? And how long is the motor'sexpected lifetime ? etc. Then we can a make full assessment according to that.

Q:Is it possible for you to develop new motors if we provide the tooling cost?

A: Yes. Please kindly share the detailed requirements like performance, size, annual quantity, target price etc. Then we'll makeour evaluation to see if we can arrange or not.

Q: What's your main motors?

A: Diameter 4mm~42mm Dc Micro Motor And Gear Motor, Auto Dc Motor, Electric Motor, Gear Motor, Mini Dc Motor, Brush Dc Motor, Brushless Dc Motor, Spur Gear Motor, Micro Motor, Vibration Motor Etc.

Q: What's the main application of the micro dc motor?

A: Our mini DC motors are widely used in Home Applications, Office Equipment, Health-Care Application, Sanitation Industry, High-Class Toy, Banking System, Electronic and Electrical Tools, Automation Industry, Bank Equipments, Payment Equipments, Vending Machines, Power Door Lock, Electric Door Lock.

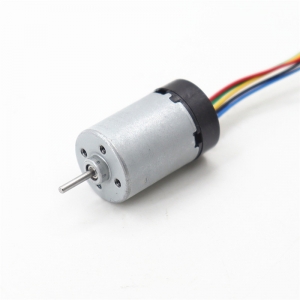

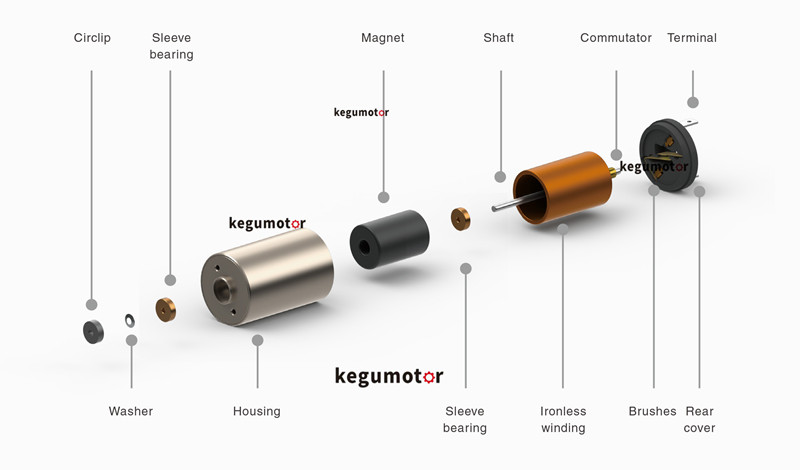

Micro DC Coreless Motor Structure

3V coreless gear motor is a high-speed, high-torque motor that is perfect for a wide range of applications. It features a high power density and low inertia, making it ideal for use in applications where space is limited. Additionally, the coreless design of this motor eliminates cogging and provides for smoother operation.

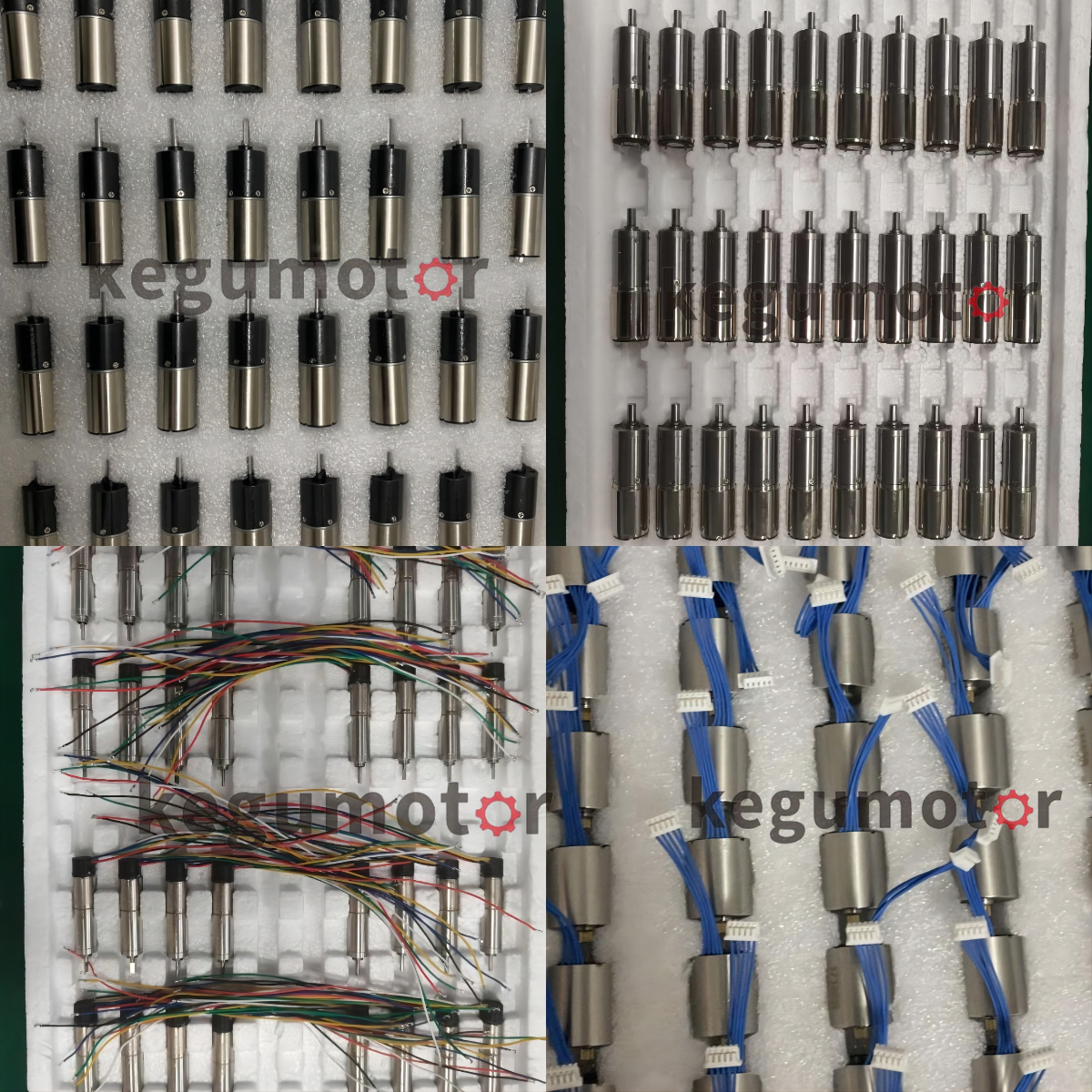

16mm Brushed Coreless Gear Motor With Encoder Mass Production

Coreless micro gear motor is a type of electric motor that uses a permanent magnet to create torque, instead of using a winding around an iron core. This makes the motor lighter and more efficient. Coreless motors are used in applications where weight and efficiency are important, such as drones and RC vehicles.

Coreless gear motors have rotor windings wound in a honeycomb form to create a self-supporting cylinder. This eliminates the mass and inertia of a rotating rotor, making rapid acceleration and deceleration possible. All of the core produces torque and smooths operation. The design also produces high acceleration rates.

You can find suitable coreless dc gear motor according to your application. The first point to consider is motor dimensions. Diameter and motor body length are two important parameters usually cannot be changed. When mass production is required, the coreless gear motor shaft length can be customized according to customer needs.

Anyway, you can tell us the requirements about the DC motor, all inquiries will be response in 24 hours.